Registered Textile exporters from India-Textile Suppliers

At Kaptaan Business Solutions, we take immense pride for our textile export from India. Our expertise and commitment to the textile export industry. With a strong focus on quality, innovation, and customer satisfaction, we are your premier partner for textile exports.

Our mission is to provide the global market with top-notch textiles that exemplify craftsmanship and excellence, making us a trusted name in the industry. Welcome to a world of textile solutions with Kaptaan Business Solutions Textile Exports.

Our Export Textile Products

Welcome to Kaptaan Business Solutions, your foremost source for top-quality textiles and being among the top garments exporters in India. With a rich heritage and a dedication to excellence, we take immense pride in our standing as a global leader in textile exports. Our diverse range of textiles and ready-made garments embodies the essence of craftsmanship, innovation, and quality that defines the top garments exporters in India.

Whether you're in search of exquisite fabrics, trendy apparel, or custom solutions, we've got you covered with a wide selection of textile products meticulously curated to cater to diverse tastes and preferences. Join hands with us, and let Kaptaan Business Solutions be your trusted partner in the world of fashion and textiles. Take the first step towards transforming your business today – contact us to discuss your needs and embark on a journey of success together!

Our textile export from India standards?

Kaptaan Business Solutions, recognized as the world's top textile exporter, upholds unwavering standards in our exports. Quality is paramount, with stringent checks ensuring our textiles, from fabrics to readymade garments, consistently exceed global benchmarks. Our commitment to ethical sourcing emphasizes sustainability and fair labor practices within the textile industry.

Our versatile customization options, ranging from unique designs to specific fabric compositions, address the unique needs of our clients.

We prioritize innovation and utilize an efficient logistics network to ensure timely delivery of our top-notch textiles. At the core of our operations is customer satisfaction, and we continually enhance our services to meet and exceed your expectations.

Textiles Sellers for India & Other Countries

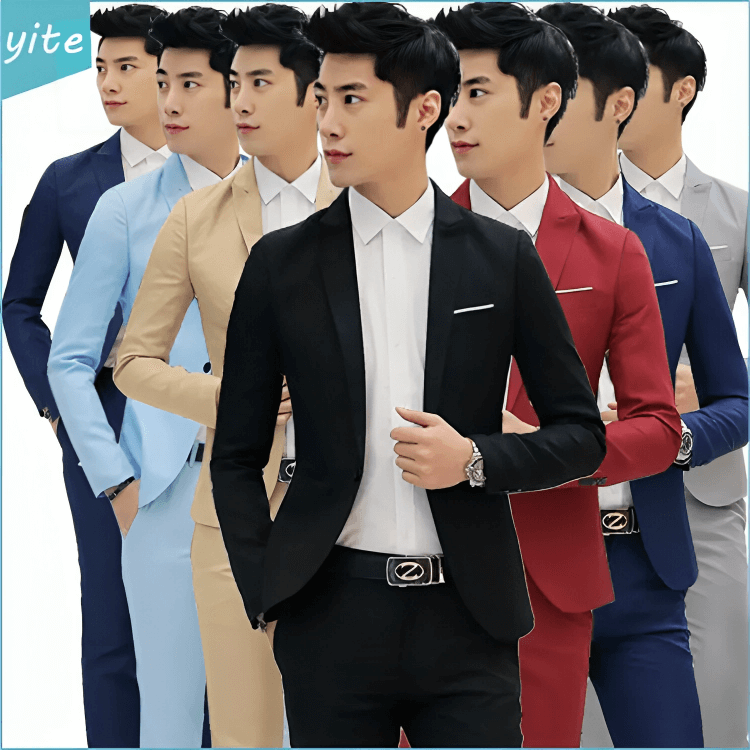

Bulk Suiting's Suppliers

Bulk Shirting's Suppliers

Bulk Blazers Suppliers

Bulk Uniforms Suppliers

Our Top Examples of Textile Products....

We supply a diverse range of textile products from India, showcasing our expertise in the textile industry. Our top-quality textiles, including fabrics and readymade garments, consistently rank among the top textile exports globally. With a strong focus on quality, sustainability, and ethical sourcing, our products meet and exceed international standards.

Our specialization in textile manufacturing, coupled with our commitment to innovation, ensures that we remain at the forefront of the textile industry. Explore our extensive range of top-notch textiles today to elevate your business, and let us be your trusted textile export partner. Your success is our unwavering commitment.

We export the following products.

We Also Supply Branded Textile Products Like...

All Kinds of Fabrics Suppliers- SUITINGS AND SHIRTINGS-READY MADE GARMENTS

Branded SUITINGS AND SHIRTINGS SUPPLIERS (Bulk Quantites)

- MAFATLAL Suitings Suppliers and Shirting Suppliers

- VALJI Suitings Suppliers and VALJI Shirting Suppliers

- QMAX Suitings Suppliers and QMAX Shirting Suppliers

- BHILWARA Suitings Suppliers and Shirting Suppliers

- GWALIOR Suitings Suppliers and Shirting Suppliers

- SIYARAMS Suiting's Suppliers and Shirting Suppliers

- ARIND Suiting's Suppliers and Shirting Suppliers

- GRASIM Suiting's Suppliers and Shirting Suppliers

- RAYMOND Suiting's Suppliers and Shirting Suppliers

- All Kinds of Uniforms (Schools, Colleges, Hospitals, Hotels, Corporate, Factories etc)

- Branded SUITINGS AND SHIRTINGS (Cotton, Polyster, Linen, Denim, Satin)

- Sports Fabrics Suppliers ( Polyster Cotton PC, Honeycomb, Super Poly, Dryfit, Dotknit,Jackbro, Seleena, Plain polyster, Locasto,Nirmal Jali, Lycra and all other Knit wears)

Top Textile Exporters and Textile Suppliers From India

Order Now As Per Your Specifications

Kaptaan Business Solutions China, India, Bangladesh Textile Exporter and Textile Supplier

Kaptaan Business Solutions offers a range of services to assist in textile businesses in sourcing and exporting their products from Textile Export Surat Gujrat India. China Textile Exporters and Bangladesh Textile Exporters. Our team of experts can help in finding the right cotton textile industries in India and the best textile suppliers, ensuring product quality, managing logistics, and handling customs processes, all while ensuring that businesses can access high-quality textiles at competitive prices as low as Surat wholesale textile market prices. Additionally, we offer consulting services to help businesses navigate the complex textile import/export process and ensure compliance with relevant regulations and requirements.

Chamber Membership 8 Best Tips for Making the Most of Your

The Best Top 10 Chamber of Commerce Events for Business Owners

Regulations to Follow When Textile Export from India

In the textile world, it's really important to follow the rules when you're buying or selling textile stuff from one place to another. This means getting the right permissions and papers, making sure it's safe and good for the environment, and doing all the paperwork correctly. Kaptaan Business Solutions can help companies make sure they do everything right. That way, there's less chance of things going wrong or getting delayed when you're moving textile products around.

Contact Us Now For More Information !

For further assistance or inquiries regarding the import or export of textile products, please feel free to contact us via email or reach out using the provided contact information.

Kaptaan Business Solutions is your trusted partner for sourcing textile export from India with best quality assurance, payment processing, logistics, and customs clearance of textile products. Reach out to us today and access the latest textile market prices and information!

Frequently Asked Questions Garments & Textile Export from India (FAQs) -

Textiles exports refer to the international trade of textile products. These products can include a wide range of textile materials, fabrics, clothing, and related items. Textiles exports involve selling these goods produced in one country to customers or businesses in other countries.

Textile exports are an essential component of the global textile industry and international trade. Countries often engage in textile exports to capitalize on their strengths in textile production, cost competitiveness, or the quality of their textile products. These exports can contribute significantly to a country's economy, generating revenue, providing employment, and promoting economic growth.

Typically, textile exports encompass various products, such as:

-

Fabric: Various types of woven and knitted fabrics used in clothing, home textiles, industrial applications, and more.

-

Apparel: Finished garments and clothing items for consumers and businesses, including dresses, shirts, pants, and more.

-

Yarn: Spun or filament yarn used as the building blocks for fabrics and textiles.

-

Home Textiles: Products like bedding, towels, curtains, and upholstery fabrics used in households and hospitality industries.

-

Technical Textiles: Textiles designed for specialized functions like automotive textiles, medical textiles, and geotextiles.

-

Accessories: Textile accessories such as belts, scarves, ties, and gloves.

Textile exports are influenced by factors like trade agreements, tariff policies, consumer preferences, and global demand. Countries with competitive advantages in terms of cost, quality, and design often excel in the textiles export market and play a significant role in the global supply chain.

Several countries around the world are known for their strong textile industries and are considered rich in textiles due to their production capabilities, quality, and historical significance in the textile trade. Some of the prominent countries known for their textile richness include:

-

China: China is the world's largest textile producer and exporter. It has a vast and diverse textile industry, producing a wide range of textiles, garments, and accessories.

-

India: India has a rich and ancient tradition of textile manufacturing, including handloom and traditional textile techniques. It's known for its production of cotton, silk, and synthetic textiles.

-

Bangladesh: Bangladesh is a major hub for textile and garment manufacturing, particularly for ready-made garments. It's one of the world's largest garment exporters.

-

Pakistan: Pakistan has a robust textile industry, known for producing cotton, denim, and other textiles. It's a significant exporter of textiles and garments.

-

Vietnam: Vietnam has emerged as a strong player in the textile and apparel industry, becoming a popular destination for textile manufacturing and export.

-

Turkey: Turkey is known for its high-quality textiles, including cotton, denim, and home textiles. It has a well-established textile industry.

-

Italy: Italy is renowned for its luxury textiles and fashion. It's known for producing high-end fabrics and couture fashion.

-

Japan: Japan has a reputation for producing high-quality textiles, including silk and traditional textiles like kimono fabric.

-

South Korea: South Korea is known for its innovative and high-tech textiles, especially in areas like functional fabrics and sportswear.

-

United States: The United States has a diverse textile industry, with a focus on technical textiles, denim, and specialty textiles.

These countries have invested heavily in their textile sectors, have a skilled workforce, and often have a long history of textile production. They play significant roles in the global textile supply chain and contribute to the worldwide availability of textiles and apparel.

However, cotton textiles, particularly cotton garments, have historically been among the most exported textile products from India. These exports include items such as cotton shirts, trousers, t-shirts, and other clothing made from cotton fabric.

India is one of the world's largest producers of cotton and has a well-established cotton textile industry. The country's cotton textiles are in high demand globally due to their quality, variety, and competitive pricing.

India imports a significant amount of clothing and textiles to meet its domestic demand and supply its retail market. The choice of the best country to import clothes to India depends on various factors, including the type of clothing, quality requirements, cost considerations, and market trends. Here are a few countries that are commonly considered for clothing imports to India:

-

China: China has long been a major source of clothing imports for India. It offers a wide range of clothing options at various price points. However, it's essential to consider factors such as quality control and compliance with trade regulations.

-

Bangladesh: Bangladesh is known for its cost-effective garment manufacturing and is a significant supplier of ready-made garments to India.

-

Vietnam: Vietnam has been gaining prominence as a clothing supplier due to its competitive pricing, skilled labor, and adherence to international quality standards.

-

Thailand: Thailand is known for its quality clothing products, especially in the high-end and luxury segments.

-

Turkey: Turkey offers high-quality textiles and clothing, with a focus on fast fashion and trendy styles.

-

Indonesia: Indonesia is another potential source for clothing imports, offering a variety of clothing styles and materials.

-

Sri Lanka: Sri Lanka is known for producing high-quality apparel, particularly in the sportswear and lingerie segments.

-

United Arab Emirates: The UAE, particularly Dubai, serves as a hub for clothing imports into India, especially for luxury and high-end fashion items.

When selecting a country for clothing imports to India, it's crucial to consider factors such as product quality, production capacity, lead times, shipping costs, and any trade agreements or tariffs that may apply. Additionally, conducting due diligence on potential suppliers and understanding the specific requirements of the Indian market will help in making an informed decision.

The future of textile exports is expected to be influenced by several key trends and factors. While it's difficult to predict the exact outcomes, the following are some of the trends and considerations that may shape the textile export industry in the coming years:

-

Sustainability and Eco-Friendly Practices: There is a growing global focus on sustainability, and the textile industry is no exception. Consumers are increasingly demanding eco-friendly and sustainable textiles. Textile exporters are likely to adapt by producing and exporting sustainable and environmentally responsible products.

-

Technological Advancements: Technology is playing a significant role in the textile industry's evolution. Advancements in manufacturing processes, such as automation, digital printing, and smart textiles, are expected to impact production capabilities and export opportunities.

-

E-Commerce and Online Retail: The growth of e-commerce has changed the way consumers shop for clothing and textiles. Textile exporters are likely to explore opportunities in online retail channels and develop strategies to reach global consumers directly.

-

Customization and Personalization: Consumers are increasingly seeking personalized products. Textile exporters may invest in technologies that allow for customization and adaptability in their product offerings.

-

Trade Agreements and Tariffs: Trade policies and agreements between countries will continue to impact the textile export landscape. Changes in tariffs and trade regulations can affect export patterns and market access.

-

Reshoring and Nearshoring: Some countries may explore the idea of bringing textile manufacturing closer to home (reshoring or nearshoring) to reduce supply chain risks and transportation costs. This could impact the dynamics of textile exports.

-

Fashion and Design Trends: Fashion and design trends play a significant role in textile exports. Staying attuned to changing consumer preferences and adapting product lines accordingly will be crucial.

-

Market Diversification: Textile exporters may look to diversify their export markets to reduce dependency on a single region or country.

-

Quality and Compliance: Maintaining high product quality and adhering to international compliance standards will continue to be essential for textile exporters to access global markets.

-

Supply Chain Resilience: Recent disruptions, such as the COVID-19 pandemic, have highlighted the importance of resilient supply chains. Exporters may invest in supply chain resilience to mitigate risks.

The textile export industry is dynamic and adaptable, and its future will depend on how industry stakeholders respond to these trends and challenges. It's likely that successful textile exporters will be those who embrace sustainability, innovation, and agility in their business strategies.

Quality standards in the textile industry are essential to ensure that textile products meet certain criteria for performance, safety, and customer satisfaction. These standards help establish consistent quality across the industry and provide guidelines for manufacturers, exporters, and consumers. Some of the key quality standards and certifications in the textile industry include:

-

ISO Standards: The International Organization for Standardization (ISO) has developed several standards relevant to the textile industry. ISO 9001 focuses on quality management systems, while ISO 14001 addresses environmental management. ISO 45001 covers occupational health and safety, and ISO 50001 focuses on energy management.

-

OEKO-TEX Standard 100: This is a widely recognized certification that verifies that textiles have been tested for harmful substances and are safe for human use. It sets limits on the use of certain chemicals and dyes in textile production.

-

GOTS (Global Organic Textile Standard): GOTS is a global standard for organic textiles. It covers the entire supply chain, from the harvesting of raw materials to labeling. GOTS-certified products must meet stringent environmental and social criteria.

-

REACH Regulation: REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is a European Union regulation that addresses the use of chemicals in the textile industry. It aims to protect human health and the environment by controlling the use of hazardous chemicals.

-

ASTM Standards: The American Society for Testing and Materials (ASTM) develops and publishes standards for textiles, including test methods for evaluating properties like strength, durability, and flammability.

-

AATCC Standards: The American Association of Textile Chemists and Colorists (AATCC) develops standards for testing and evaluating various textile properties, including colorfastness, abrasion resistance, and water repellency.

-

EN Standards: The European Committee for Standardization (CEN) has developed numerous textile-related standards, including those for labeling, safety, and performance.

-

CPSIA (Consumer Product Safety Improvement Act): This U.S. law sets safety standards for children's products, including textiles and clothing, to protect children from potential hazards.

-

FSC (Forest Stewardship Council): FSC certification is relevant for textiles made from wood-based fibers like viscose and modal. It ensures that wood and pulp used in textile production come from responsibly managed forests.

-

ISO 12945 (Pilling Resistance): This standard evaluates a textile's resistance to pilling (the formation of small balls of fibers on the fabric surface), which is an important aspect of fabric quality.

-

ISO 13934 (Tensile Strength and Elongation): This standard measures a textile's tensile strength and elongation to assess its durability and performance under stress.

These are just a few examples of the quality standards and certifications that apply to the textile industry. The specific standards and requirements can vary depending on the type of textile product, its intended use, and the region in which it is produced or sold. Manufacturers and exporters in the textile industry must adhere to these standards to ensure product quality and safety for consumers.

Textiles encompass a wide variety of materials and products. Here are some examples of textiles:

-

Cotton Fabric: Cotton is one of the most commonly used natural fibers for textiles, producing a wide range of fabrics like cotton twill, denim, and muslin.

-

Silk Fabric: Known for its luxurious feel and sheen, silk is used to make a variety of textiles, including silk charmeuse, silk chiffon, and silk satin.

-

Wool Fabric: Wool is used to create warm and durable textiles such as wool suits, sweaters, and blankets.

-

Linen Fabric: Linen is a natural fiber used to make breathable and lightweight textiles, often used in summer clothing.

-

Polyester Fabric: A synthetic fiber, polyester is versatile and commonly used for textiles like polyester satin, polyester blends, and fleece.

-

Nylon Fabric: Nylon is known for its strength and elasticity and is used in textiles like nylon spandex, nylon blends, and nylon taffeta.

-

Rayon Fabric: Rayon is a semi-synthetic fiber that mimics the qualities of natural fibers and is used for textiles like rayon crepe and rayon challis.

-

Denim: A durable cotton fabric, denim is often used for jeans, jackets, and other casual clothing.

-

Velvet: Velvet is a plush and luxurious textile known for its soft feel and is used for various clothing and upholstery.

-

Fleece: Fleece textiles are soft, warm, and commonly used for jackets, blankets, and activewear.

-

Tulle: Tulle is a lightweight, fine netting fabric used in bridal wear and ballet tutus.

-

Canvas: Canvas textiles are sturdy and often used for bags, tents, and artist canvases.

-

Chiffon: Chiffon is a sheer and lightweight fabric, commonly used in eveningwear and lingerie.

-

Satin: Satin is a glossy and smooth fabric used for formalwear, lingerie, and accessories.

-

Twill: Twill is a durable fabric with a distinctive diagonal weave used in items like khaki pants and denim.

-

Burlap: Burlap is a coarse, woven fabric typically used for sacks, bags, and gardening purposes.

-

Georgette: Georgette is a lightweight, sheer fabric used in clothing and scarves.

-

Flannel: Flannel textiles are soft and warm, often used in pajamas, shirts, and bedding.

-

Jersey: Jersey is a stretchy and comfortable knit fabric used for T-shirts, dresses, and sportswear.

-

Terry Cloth: Terry cloth is highly absorbent and is used for towels, bathrobes, and baby products.

These are just a few examples of the diverse range of textiles used for various purposes, from clothing to home furnishings.

The textile industry process involves a series of steps to produce various textile products, from raw materials like fibers to finished goods such as clothing, upholstery, and industrial fabrics. This process can be quite complex and varies depending on the type of textile and the intended end product. Here is an overview of the typical stages in the textile industry process:

-

Fiber Production: The process begins with the production of fibers, which can be natural (e.g., cotton, wool, silk) or synthetic (e.g., polyester, nylon). Natural fibers are harvested, while synthetic fibers are chemically produced.

-

Preparation: Fibers go through various preparation processes, which may include cleaning, carding (to align fibers), and blending (mixing different fibers for specific characteristics).

-

Spinning: In this stage, prepared fibers are spun into yarn or thread. This process twists the fibers together to create a continuous strand.

-

Weaving or Knitting: Yarns are used to create the fabric structure through weaving (over-under pattern) or knitting (looped structure). Weaving is used for fabrics like cotton, denim, and silk, while knitting is used for products like T-shirts and sweaters.

-

Dyeing and Printing: The fabric may be dyed or printed to add color and patterns. This process can be done at various stages, depending on the desired outcome.

-

Finishing: After dyeing or printing, fabrics may go through finishing processes like singeing (removing loose fibers), calendaring (smoothing the surface), or applying coatings for specific properties (e.g., water repellency).

-

Cutting and Sewing: For apparel production, the fabric is cut into pattern pieces, which are then sewn together to create clothing items.

-

Quality Control: Throughout the entire process, quality control measures are applied to ensure the final product meets the desired specifications.

-

Packaging and Distribution: Once the textile product is completed, it is packaged and prepared for distribution to wholesalers, retailers, or consumers.

The textile industry process can vary significantly based on the type of product being manufactured, whether it's clothing, home textiles, industrial fabrics, or technical textiles. Additionally, the industry has seen significant technological advancements, including the use of automation and digital technologies, which have streamlined and improved various stages of production. Sustainable practices and environmental considerations are also becoming increasingly important in the textile industry.

Fabric is a flexible and often woven material composed of fibers or threads. It is a fundamental component in the textile industry and is used to make a wide range of products, including clothing, upholstery, linens, and more. Fabrics can be produced from natural fibers, synthetic fibers, or a blend of both. Here are some key aspects of fabric:

-

Composition: Fabrics are made from fibers, which can be natural (like cotton, silk, wool, or linen), synthetic (such as polyester, nylon, or rayon), or a blend of both. The type of fiber used influences the fabric's properties, including texture, strength, and durability.

-

Weaving: Most fabrics are created through a weaving process, where vertical (warp) and horizontal (weft) threads are interlaced to form a fabric structure. Different weaving patterns and techniques result in different fabric textures and characteristics.

-

Knitting: Some fabrics, like jersey or sweater knits, are produced through a knitting process rather than weaving. Knitted fabrics are constructed by interlocking loops of yarn.

-

Types: Fabrics come in a wide variety of types, each with unique properties. These include cotton, silk, denim, velvet, tulle, chiffon, satin, and many others. Each type is suited for specific uses based on its characteristics.

-

Applications: Fabrics are used in numerous applications, such as clothing, home textiles (bedding, curtains, upholstery), accessories (bags, scarves), industrial products (tarps, filters), and more.

-

Properties: Fabric properties can vary widely depending on the type of fiber used and the weaving or knitting technique. These properties include texture, strength, durability, drape, breathability, and elasticity.

-

Dyeing and Printing: Fabrics can be dyed or printed with various colors and patterns to create a wide range of designs and styles.

-

Care: Different fabrics may require specific care and cleaning methods. For example, some fabrics are machine-washable, while others may need dry cleaning.

Fabrics play a vital role in the fashion and textile industry, and their versatility and diversity make them essential for creating a wide array of products to meet various needs and preferences.

The fabric manufacturing process involves turning raw materials, such as fibers, into finished fabric through a series of steps. The specific process can vary depending on the type of fabric and its intended use, but here is a general overview of the fabric manufacturing process:

-

Fiber Production: The process starts with the production of fibers, which can be natural (cotton, wool, silk, etc.) or synthetic (polyester, nylon, etc.). These fibers may be sourced from various locations, depending on the type of fabric being manufactured.

-

Preparation of Fibers: Natural fibers often need to be cleaned and processed to remove impurities and prepare them for spinning. This can involve carding, which aligns the fibers and removes foreign matter.

-

Spinning: In this stage, the prepared fibers are spun into yarn. Spinning involves twisting the fibers together to create a continuous strand of yarn.

-

Yarn Formation: Depending on the desired fabric type, different types of yarn can be created. For example, some fabrics require single yarns, while others use plied yarns (two or more yarns twisted together).

-

Weaving or Knitting: The yarn is used to create the fabric structure through either weaving or knitting. Weaving involves an over-under pattern of yarns on a loom and is used for fabrics like denim or cotton. Knitting creates a looped structure and is used for products like T-shirts and sweaters.

-

Dyeing and Printing: After the fabric is created, it may go through processes like dyeing and printing to add color and patterns. This can occur at various stages, depending on the desired outcome.

-

Finishing: Finished fabric is often processed to achieve specific characteristics or appearances. This can involve processes like singeing (removing loose fibers), calendaring (smoothing the surface), or applying coatings (e.g., water repellency).

-

Quality Control: Throughout the entire process, quality control measures are applied to ensure the final fabric meets the desired specifications.

-

Cutting and Sewing: For clothing production, the fabric is cut into pattern pieces, which are then sewn together to create clothing items.

-

Packaging and Distribution: Once the fabric is completed, it is packaged and prepared for distribution to manufacturers, retailers, or consumers.

The fabric manufacturing process can be quite intricate, and variations occur based on factors like fiber type, end use, and technological advancements. Automation and digital technologies have also become more prevalent in the fabric manufacturing industry, increasing efficiency and precision. Sustainable practices, such as using eco-friendly dyes and reducing waste, are increasingly important in modern fabric manufacturing.